Products

11km high pressure forced draft fan, Bag type dust remover -changhao

11km high pressure forced draft fan, Bag type dust remover -changhao Detail:

Main Feature

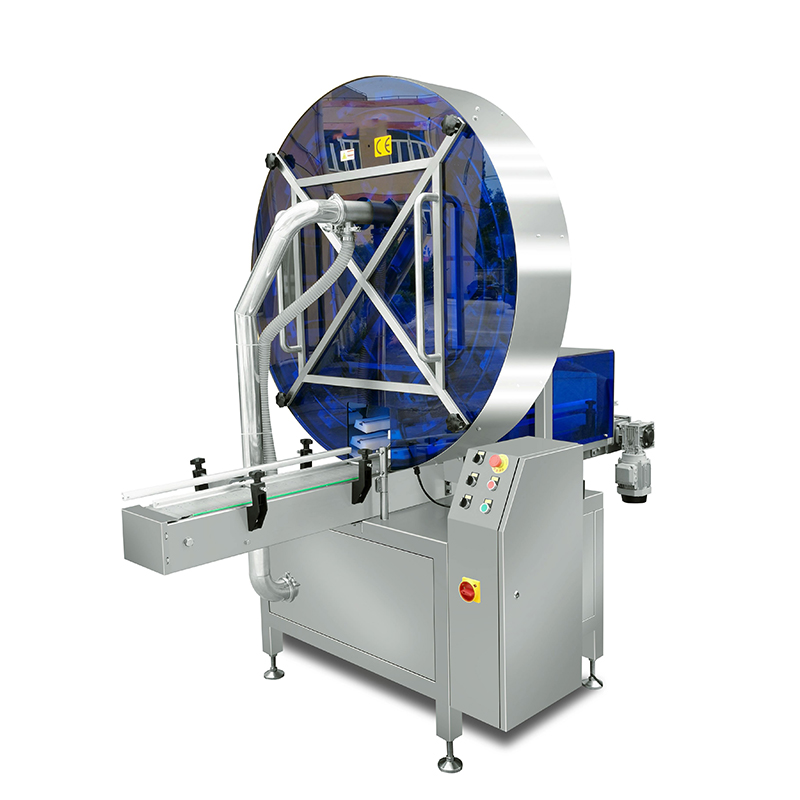

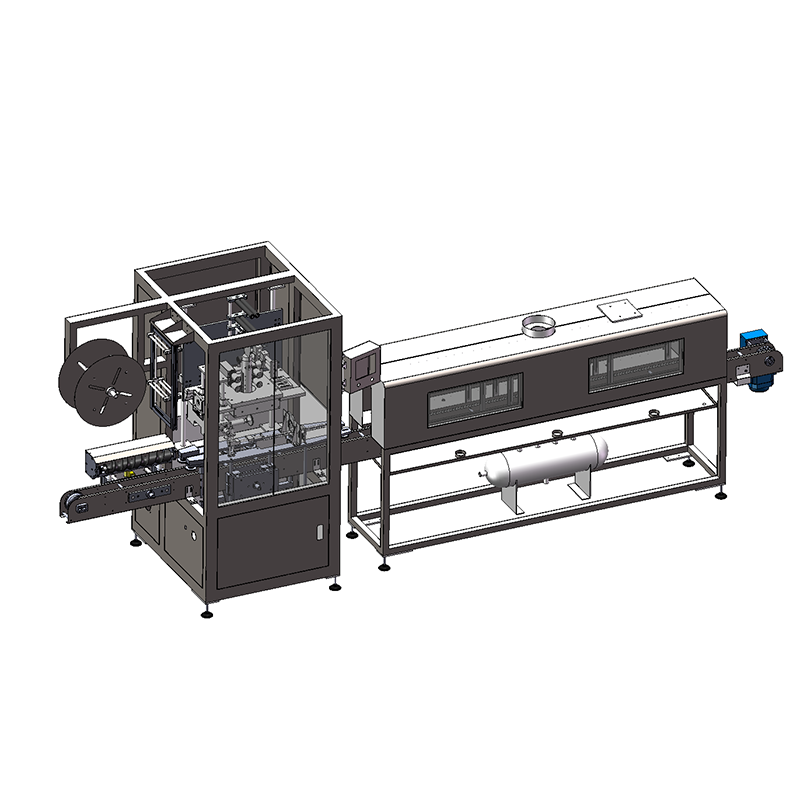

The bag filter is a dry dust filter device. It is suitable for capturing fine, dry, non-fibrous dust. The filter bag is made of textile filter cloth or non-woven felt, and uses the filter function of the fiber fabric to filter the dusty gas. When the dusty gas enters the bag filter, the dust with large particles and specific gravity will be separated by gravity. The dust settles down and falls into the ash hopper. When the gas containing fine dust passes through the filter material, the dust is filtered and the gas is purified.

The bag filter is a dry dust filter device. After the filter material is used for a period of time, a layer of dust accumulates on the surface of the filter bag due to effects such as screening, collision, retention, diffusion, and static electricity. This layer of dust is called the initial layer. In the next working process, the initial layer becomes The main filter layer of the filter material, relying on the role of the initial layer, the filter material with a larger mesh can also obtain higher filtration efficiency. With the accumulation of dust on the surface of the filter material, the efficiency and resistance of the dust collector will increase accordingly. When the pressure difference on both sides of the filter material is large, some fine dust particles that have adhered to the filter material will be squeezed out. In this way, the efficiency of the dust collector will decrease. Besides, the high resistance power will dramatically lower air volume of the dust collecting system. Therefore, after the resistance of the dust collector reaches a certain value, the dust should be cleaned immediately. When cleaning the dust, please do not damage the first layer in case the filtering effect will decline.

Working Principle

The high dust removal efficiency of the bag filter is inseparable from its dust removal mechanism. When the dust-laden gas enters the ash hopper from the air inlet pipe at the lower part of the dust collector through the deflector, the coarse dust will fall into the ash hopper due to the collision of the deflector and the reduction of the gas velocity.Other fine particles of dust enter the filter bag chamber with the gas. Due to the inertia, diffusion, barrier, hooking, static electricity and other effects of the filter fiber and fabric, the dust is blocked in the filter bag, and the purified gas escapes out of the bag, and then Exits through the exhaust pipe.The dust accumulated on the filter bag is removed by the gas reverse cleaning method, and the removed dust falls into the ash hopper, and is discharged to the dust conveying device through the double-layer ash discharge valve. The accumulated dust on the filter bag can also be removed by blowing pulse airflow, so as to achieve the purpose of dust removal,The removed dust is discharged by the ash discharge device. The high dust removal efficiency of the bag filter is also inseparable from the filter material. The performance and quality of the filter material are directly related to the performance and service life of the bag filter. The filter material is the main material for making filter bags. Its performance and quality promote the progress of bag dust removal technology and affect its application range and service life.

The filter dust removal device includes a bag filter and a granular layer dust collector. The former usually uses a filter bag made of organic fiber or inorganic fiber fabric as the filter layer, while the filter layer of the latter mostly uses particles of different particle sizes, such as quartz sand, Composed of river sand, ceramsite, slag, etc. As the powder repeatedly adheres to the outer surface of the filter bag, the powder layer continues to thicken, and the resistance value of the bag filter also increases; the pulse valve diaphragm sends out instructions, and the pulse valve opens when the left and right submerge, and the compression in the high-pressure air bag The air is ventilated, if there is no dust or it is small to a certain extent, the mechanical cleaning work will stop working.

The gas purification method of the low-pressure pulse bag filter is the external filter type, and the dust-laden gas enters the filter chambers of each unit through the guide tube. Due to the vertical distance between the bottom of the filter bag and the upper port of the air inlet in the design, there is sufficient and reasonable air flow through the appropriate guide. The air flow and natural flow direction are distributed to achieve uniform air distribution in the entire filter room. The particles and dust in the dusty gas are separated by natural sedimentation and then directly fall into the ash hopper. Under the guidance of the diversion system, the remaining dust enters the filter area of the middle box with the airflow. , adsorbed on the outer surface of the filter bag. The filtered clean gas is discharged through the filter bag through the upper box and the exhaust pipe.

The filter bag is cleaned by compressed air, and the cleaning mechanism is composed of an air bag, a blowing pipe and an electromagnetic pulse control valve. An air blowing pipe is installed on the top of the outlet of each row of filter bags in the filter chamber. The bottom of the air blowing pipe is directly facing the center of the filter bag with an air blowing port. Each air blowing pipe is equipped with a pulse valve connected to the compressed air bag. When cleaning dust, the solenoid valve opens the pulse valve, and the compressed air passes through the blowing port. The cleaning control device (differential pressure or timing, manual control) opens the electric pulse blowing according to the set program. The pulse valve induces the air several times the jet volume into the filter bag through the nozzle on the blowing pipe. The air wave is formed, which causes the filter bag to produce rapid expansion and impact vibration from the mouth of the bag to the bottom, resulting in a strong cleaning effect and shaking off the dust on the filter bag.

Advantage

(1) The dust removal efficiency is high, generally above 99%, the dust concentration in the outlet gas of the dust collector is within tens of mg/cubic meter, and the classification efficiency for fine dust with submicron particle size is high.

(2) The range of air volume is wide, the small one is only a few cubic meters per minute, and the large one can reach tens of thousands of cubic meters per minute. It can be used for flue gas dust removal of industrial furnaces and reduce the emission of air pollutants.

(3) Simple structure, easy maintenance and operation.

(4) Under the premise of ensuring the same high dust removal efficiency, the cost is lower than that of the electrostatic precipitator.

(5) When using glass fiber, polytetrafluoroethylene, P84 and other high temperature resistant filter materials, it can operate under high temperature conditions above 200 °C. (6) It is not sensitive to the characteristics of dust and is not affected by dust and electrical resistance.

Product detail pictures:

Related Product Guide:

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for 11km high pressure forced draft fan, Bag type dust remover -changhao , The product will supply to all over the world, such as: Argentina , Mauritius , Cape Town , We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality products and good after-sales services. Up to now, our products have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.