Products

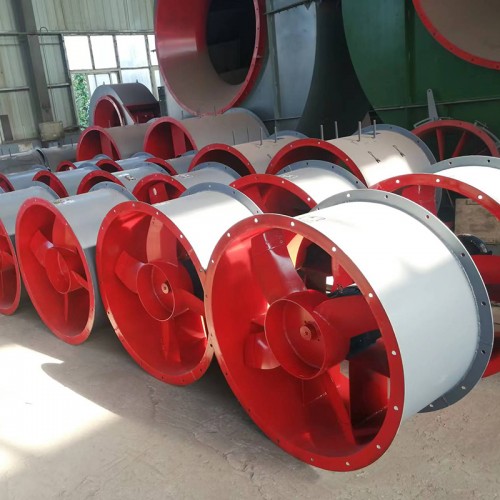

Axial Flow Fan

Use and Type

Axial flow fans are widely used for ventilation in general factories, warehouses, offices, and residences or to increase heating and heat dissipation. If the casing is removed, it can be used as a free fan, or it can be installed in series at intervals in a long exhaust duct to increase the wind pressure in the duct.

There are 46 varieties of this fan, among which there are nine machine numbers with 3 blades, 6 blades, 8 blades and 9 blades. According to the diameter of the impeller, they are arranged in order from small to large: №3, №3.5, №4, №5, 6, 7, №8, №9, №10: 4 blades have ten machine numbers in total, according to the diameter of the impeller, they are arranged in descending order: №2.5, N3, №3.5, №4, №5, №6, №7, №8, №9, N10.

The fan consists of three parts: impeller, casing and air collector:

Impeller: It consists of blades, hubs, etc. The blades are stamped and formed with thin steel plates, and welded to the outer circle of the hub according to the required installation angle. The impeller shell ratio (the ratio of the diameter of the shaft disc to the diameter of the impeller) d=0.3.

Blades: all stamped into similar shapes, and their installation angles: 3 pieces are divided into five types: 100, 150, 200, 250, and 300.

4, 6, and 8 pieces are divided into five types: 15°, 20°, 25°, 30°, and 35°. The impeller is directly installed on the motor shaft, among which №3 to N8 adopt two motor speeds, and №9 and №10 adopt one motor speed, the air volume range is 550~49500 cubic meters per hour, and the air pressure range is 25~505Pa

Chassis: It is composed of air duct, chassis, etc. The chassis is divided into two types made of thin plates and profiles.

Air collector: The air collector is arc-shaped and streamlined, which is stamped from a thin plate to reduce energy loss at the inlet. It has been proved by experiments and use that the fan is reasonable in design and compact in structure. At each specified speed, the wind pressure and air volume are stable, the operation is stable and good, safe, reliable, durable.

Note: The gas passing through the fan should be non-corrosive, non-spontaneous, and free from significant dust, and its temperature should not exceed 45°C.

BT30 explosion-proof axial flow fan, the impeller part is made of aluminum (except the shaft disk), the power is changed to an explosion-proof motor, and an explosion-proof switch is used or the switch is far away from the explosive point. The other parts are made of the same material as the axial flow fan. It is mainly suitable for chemical, pharmaceutical, textile and other industries and for discharging flammable, explosive, and volatile gases. The installation process and other processes are the same as those of the axial flow fan.