Products

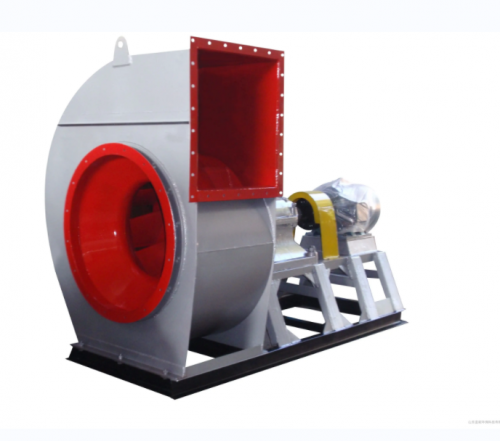

Industrial Boiler General Fan 7-41

Describe

The main features of the 7-41 type industrial boiler ventilation fan are: high fan efficiency, high total pressure, low noise, flat performance curve, wide economic use area, and the use of backward plate-shaped blades. The internal pressure efficiency is 86.5%

Noise index (ratio A sound level) LS=11.5 decibels, these two indexes are the same as those of various industrial boilers currently available in China

Compared with other types of fans, they are at the best level. If the fan reaches the same flow rate and pressure as other models, the number of rotations of the fan shaft can be increased.

The amplitude is reduced (generally by 200~800 rpm), so that the noise of the fan is significantly reduced and the operation is stable and reliable.

The medium conveyed by the ventilator is air, and the maximum temperature shall not exceed 80°C. The medium conveyed by the induced draft fan is flue gas. Under the same flow rate, the pressure of the induced draft fan can be increased by more than 30% compared with the original 5-47 boiler induced draft fan. Therefore, it is especially suitable for 1~20T/h industrial boilers with spiral pipes and multi-tube dust collectors.

Type and structure

1. Both the ventilator and the induced draft fan are made of single suction; the ventilator has six models of №4.5, 5.6, 7.1, 8, 9, and 12.5, and the induced draft fan has №4.5, 5.6, 7.1, 9, 10, 11, 11.2, 12.5 Eight machine numbers.

2. The ventilation fan can be made into two types of left rotation or right rotation. Looking up at the fan from one end of the transmission group, if the impeller rotates clockwise, it is called right rotation, which is represented by “right”. Counterclockwise rotation is called left rotation, denoted by “left”.

3. The position of the air outlet of the fan is indicated by the angle of the air outlet of the casing. “Left” and “right” can be made into three angles of 0°, 90° and 180°.

4. The transmission mode of the fan is A type, C type and D type.

The fan is composed of impeller, casing, air inlet, transmission group and regulating door.

1. Impeller: The backward inclined blade is welded between the arc-cone wheel cover and the flat wheel disc. After dynamic and static balance correction and over-speed operation test, it runs smoothly and has a long service life.

2. Chassis: welded with steel plates to form a volute casing. “Left” and “right” above N28 are common.

3. Transmission group: the main shaft is made of high-quality steel, using ball bearings, and the N4.5~7.1C transmission adopts the overall two-opening

The bearing seat is self-cooling with No. 2 calcium sodium base grease and fan blades, and the structure is simple.

4. Air inlet: The divergent air inlet is made into an integral structure and fixed on the inlet side of the casing with bolts.

5. Adjustment door: adjust the fan flow. Fans of N9 and below adopt a 3-blade louver structure, which is flexible to close and simple in structure